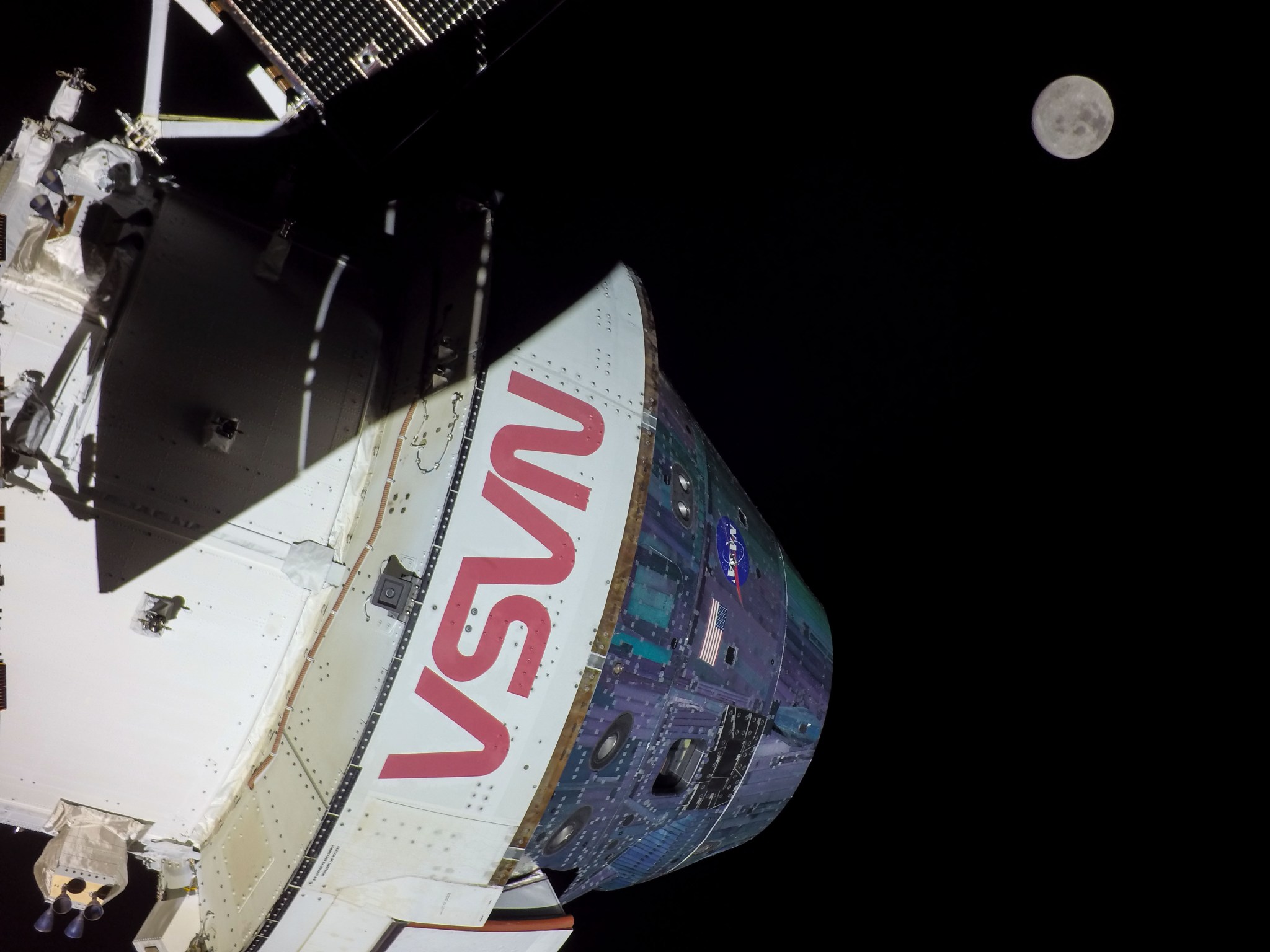

A thermal protection material for the Artemis Generation  On the 19th day of the Artemis I mission, the Moon grows larger in frame as Orion prepares for the return powered flyby on Dec. 5, when it will pass approximately 79 miles above the lunar surface. This image includes both the Orion crew module and service module, connected by the compression pad that utilizes the 3D-MAT material.NASA The 3-Dimensional Multifunctional Ablative Thermal Protection System (3D-MAT) is a thermal protection material developed as a critical component of Orion, NASA’s newest spacecraft built for human deep space missions. It is able to maintain a high level of strength while enduring extreme temperatures during re-entry into Earth’s atmosphere at the end of Artemis missions to the Moon. 3D-MAT has become an essential piece of technology for NASA’s Artemis campaign that will establish the foundation for long-term scientific exploration at the Moon and prepare for human expeditions to Mars, for the benefit of all.

On the 19th day of the Artemis I mission, the Moon grows larger in frame as Orion prepares for the return powered flyby on Dec. 5, when it will pass approximately 79 miles above the lunar surface. This image includes both the Orion crew module and service module, connected by the compression pad that utilizes the 3D-MAT material.NASA The 3-Dimensional Multifunctional Ablative Thermal Protection System (3D-MAT) is a thermal protection material developed as a critical component of Orion, NASA’s newest spacecraft built for human deep space missions. It is able to maintain a high level of strength while enduring extreme temperatures during re-entry into Earth’s atmosphere at the end of Artemis missions to the Moon. 3D-MAT has become an essential piece of technology for NASA’s Artemis campaign that will establish the foundation for long-term scientific exploration at the Moon and prepare for human expeditions to Mars, for the benefit of all.

The 3D-MAT project emerged from a technical problem in early designs of the Orion spacecraft. The compression pad—the connective interface between the crew module, where astronauts reside, and the service module carrying power, propulsion, supplies, and more—was exhibiting issues during Orion’s first test flight, Exploration Flight Test-1, in 2014. NASA engineers realized they needed to find a new material for the compression pad that could hold these different components of Orion together while withstanding the extremely high temperatures of atmospheric re-entry. Using a 3D weave for NASA heat shield materials had been explored, but after the need for a new material for the compression pad was discovered, development quickly escalated.

This led to the evolution of 3D-MAT, a material woven with quartz yarn and cyanate ester resin in a unique three-dimensional design. The quartz yarn used is like a more advanced version of the fiberglass insulation you might have in your attic, and the resin is essentially a high-tech glue. These off-the-shelf aerospace materials were chosen for their ability to maintain their strength and keep heat out at extremely high temperatures. 3D-MAT is woven together with a specialized loom, which packs the yarns tightly together, and then injected with resin using a unique pressurized process. The result is a high-performance material that is extremely effective at maintaining strength when it’s hot, while also insulating the heat from the spacecraft it is protecting.

The 3D-MAT thermal protection material.NASA Within three years, 3D-MAT went from an early-stage concept to a well-developed material and has now been integrated onto NASA’s flagship Artemis campaign. The use of 3D-MAT in the Orion spacecraft’s compression pad during the successful Artemis I mission demonstrated the material’s essential role for NASA’s human spaceflight efforts. This development was made possible within such a short span of time because of the team’s collaboration with small businesses including Bally Ribbon Mills, which developed the weaving process, and San Diego Composites, which co-developed the resin infusion procedure with NASA.

The 3D-MAT thermal protection material.NASA Within three years, 3D-MAT went from an early-stage concept to a well-developed material and has now been integrated onto NASA’s flagship Artemis campaign. The use of 3D-MAT in the Orion spacecraft’s compression pad during the successful Artemis I mission demonstrated the material’s essential role for NASA’s human spaceflight efforts. This development was made possible within such a short span of time because of the team’s collaboration with small businesses including Bally Ribbon Mills, which developed the weaving process, and San Diego Composites, which co-developed the resin infusion procedure with NASA.

The team behind its development won the NASA Invention of the Year Award, a prestigious honor recognizing how essential 3D-MAT was for the successful Artemis flight and how significant it is for NASA’s future Artemis missions. The inventor team recognized includes Jay Feldman and Ethiraj Venkatapathy from NASA’s Ames Research Center in California’s Silicon Valley, Curt Wilkinson of Bally Ribbon Mills, and Ken Mercer of Dynovas.

3D-MAT has applications beyond NASA as well. Material processing capabilities enabled by 3D-MAT have led to other products such as structural parts for Formula One racecars and rocket motor casings. Several potential uses of 3D-MAT in commercial aerospace vehicles and defense are being evaluated based on its properties and performance.

Milestones

Winner of NASA Invention of the Year Award in 2023 Flown on Artemis I in 2022 Being assessed for use by multiple Department of Defense and commercial aerospace entities Partners The 3D-MAT project is led out of NASA Ames with the support of various partners, including Bally Ribbon Mills, NASA’s Johnson Space Center in Houston, and NASA’s Langley Research Center in Hampton, Viginia, with the support of the Game Changing Development Program through NASA’s Space Technology Mission Directorate.

Learn more NASA release: First 3D woven composite for NASA thermal protection systems (March 29, 2016) NASA release: Advancements in Thermal Protection Materials Change the Game for Orion (April 3, 2015) NASA Spinoff release: 3D Weaving Technology Strengthens Spacecraft, Race Cars (2017)

For researchers NASA Technology Transfer Program webpage: Multifunctional Ablative Thermal Protection System, 3D-MAT Technical paper: “Development of an Ablative 3D Quartz/Cyanate Ester Composite for the Orion Spacecraft Compression Pad,” by Feldman, J. D., Venkatapathy, E., Wilkinson, C., and Mercer, K. J SAMPE TP15-0195, Composites and Advanced Materials Expo, Dallas Convention Center, Dallas, TX, Oct. 2015

For news media Members of the news media interested in covering this topic should reach out to the NASA Ames newsroom.