Imagine designing technology that can survive on the Moon for up to a decade, providing a continuous energy supply. NASA selected three companies to develop such systems, aimed at providing a power source at the Moon’s South Pole for Artemis missions.

Three companies were awarded contracts in 2022 with plans to test their self-sustaining solar arrays at the Johnson Space Center’s Space Environment Simulation Laboratory (SESL) in Houston, specifically in Chamber A in building 32. The prototypes tested to date have undergone rigorous evaluations to ensure the technology can withstand the harsh lunar environment and deploy the solar array effectively on the lunar surface.

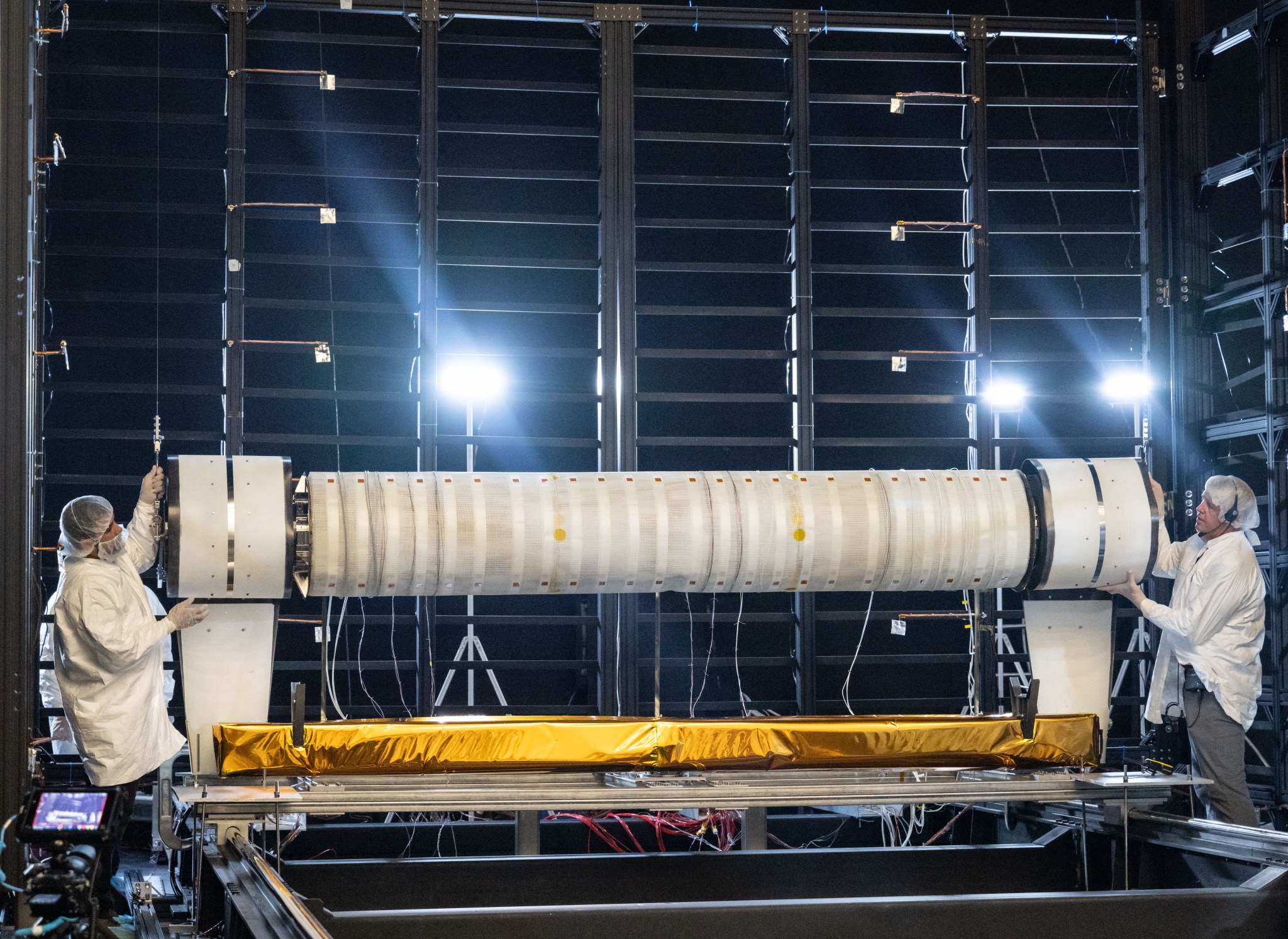

The Honeybee Robotics prototype during lunar VSAT (Vertical Solar Array Technology) testing inside Chamber A at NASA’s Johnson Space Center in Houston.NASA/David DeHoyos

The Honeybee Robotics prototype during lunar VSAT (Vertical Solar Array Technology) testing inside Chamber A at NASA’s Johnson Space Center in Houston.NASA/David DeHoyos  The Astrobotic Technology prototype during lunar VSAT testing inside Chamber A at Johnson Space Center. NASA/James Blair In the summer of 2024, both Honeybee Robotics, a Blue Origin company from Altadena, California and Astrobotic Technology from Pittsburgh, Pennsylvania put their solar array concepts to the test in Chamber A.

The Astrobotic Technology prototype during lunar VSAT testing inside Chamber A at Johnson Space Center. NASA/James Blair In the summer of 2024, both Honeybee Robotics, a Blue Origin company from Altadena, California and Astrobotic Technology from Pittsburgh, Pennsylvania put their solar array concepts to the test in Chamber A.

Each company has engineered a unique solution to design the arrays to withstand the harsh lunar environment and extreme temperature swings. The data collected in the SESL will support refinement of requirements and the designs for future technological advancements with the goal to deploy at least one of the systems near the Moon’s South Pole.

The contracts for this initiative are part of NASA’s VSAT (Vertical Solar Array Technology) project, aiming to support the agency’s long-term lunar surface operations. VSAT is under the Space Technology Mission Directorate Game Changing Development program and led by the Langley Research Center in Hampton, Virginia, in collaboration with Glenn Research Center in Cleveland.

“We foresee the Moon as a hub for manufacturing satellites and hardware, leveraging the energy required to launch from the lunar surface,” said Jim Burgess, VSAT lead systems engineer. “This vision could revolutionize space exploration and industry.”

Built in 1965, the SESL initially supported the Gemini and Apollo programs but was adapted to conduct testing for other missions like the Space Shuttle Program and Mars rovers, as well as validate the design of the James Webb Space Telescope. Today, it continues to evolve to support future Artemis exploration.

Johnson’s Front Door initiative aims to solve the challenges of space exploration by opening opportunities to the public and bringing together bold and innovative ideas to explore new destinations.

“The SESL is just one of the hundreds of unique capabilities that we have here at Johnson,” said Molly Bannon, Johnson’s Innovation and Strategy specialist. “The Front Door provides a clear understanding of all our capabilities and services, the ways in which our partners can access them, and how to contact us. We know that we can go further together with all our partners across the entire space ecosystem if we bring everyone together as the hub of human spaceflight.”

Chamber A remains as one of the largest thermal vacuum chambers of its kind, with the unique capability to provide extreme deep space temperature conditions down to as low as 20 Kelvin. This allows engineers to gather essential data on how technologies react to the Moon’s severe conditions, particularly during the frigid lunar night where the systems may need to survive for 96 hours in darkness.

“Testing these prototypes will help ensure more safe and reliable space mission technologies,” said Chuck Taylor, VSAT project manager. “The goal is to create a self-sustaining system that can support lunar exploration and beyond, making our presence on the Moon not just feasible but sustainable.”

The power generation systems must be self-aware to manage outages and ensure survival on the lunar surface. These systems will need to communicate with habitats and rovers and provide continuous power and recharging as needed. They must also deploy on a curved surface, extend 32 feet high to reach sunlight, and retract for possible relocation.

“Generating power on the Moon involves numerous lessons and constant learning,” said Taylor. “While this might seem like a technical challenge, it’s an exciting frontier that combines known technologies with innovative solutions to navigate lunar conditions and build a dynamic and robust energy network on the Moon.”

Watch the video below to explore the capabilities and scientific work enabled by the thermal testing conducted in Johnson’s Chamber A facility.